From Chaos to Clarity: Revolutionizing Manufacturing with S&OP

Jul 18, 2024

In today's fast-paced business environment, manufacturers face a constant challenge: aligning supply with demand. This age-old struggle can make or break a company's success.

But what if there was a way to bring order to this chaos?

Enter Sales & Operations Planning (S&OP) - the game-changer that's revolutionizing the manufacturing industry.

The Supply-Demand Dilemma

Every manufacturer aims to achieve that perfect equilibrium where supply meets demand.

However, the consequences of missing this mark can be severe:

Understocking leads to missed sales targets, empty shelves, and dissatisfied customers.

Overstocking results in increased warehouse costs, risk of obsolescence, and reduced profitability.

S&OP: The Bridge to Balance

S&OP is an integrated management process that aligns all business functions towards a common goal: optimizing supply to meet demand while maximizing profitability.

It brings together key departments - Sales, Marketing, Planning, Finance, Procurement, Manufacturing, and Supply Chain - to create a cohesive strategy.

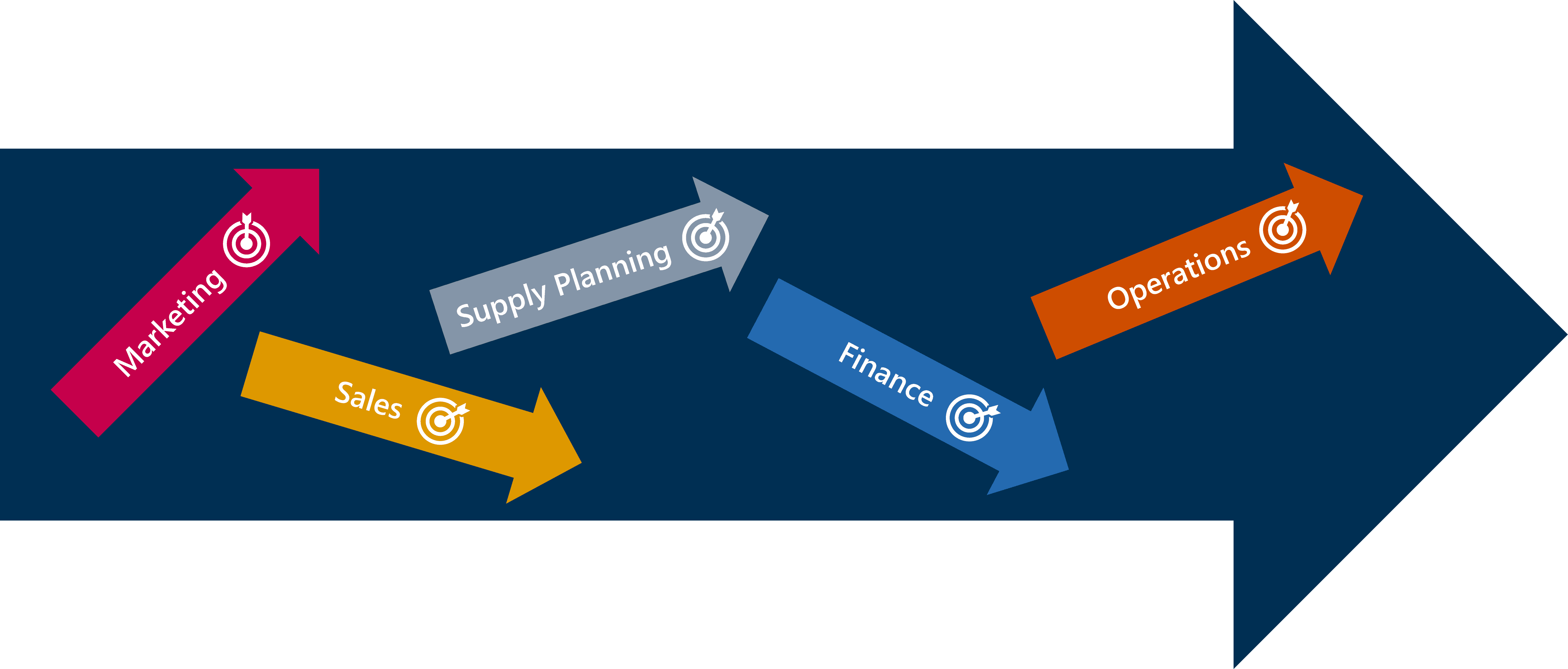

No Alignment in Sales & Operations Planning Among Different Departments of Manufacturing Enterprise

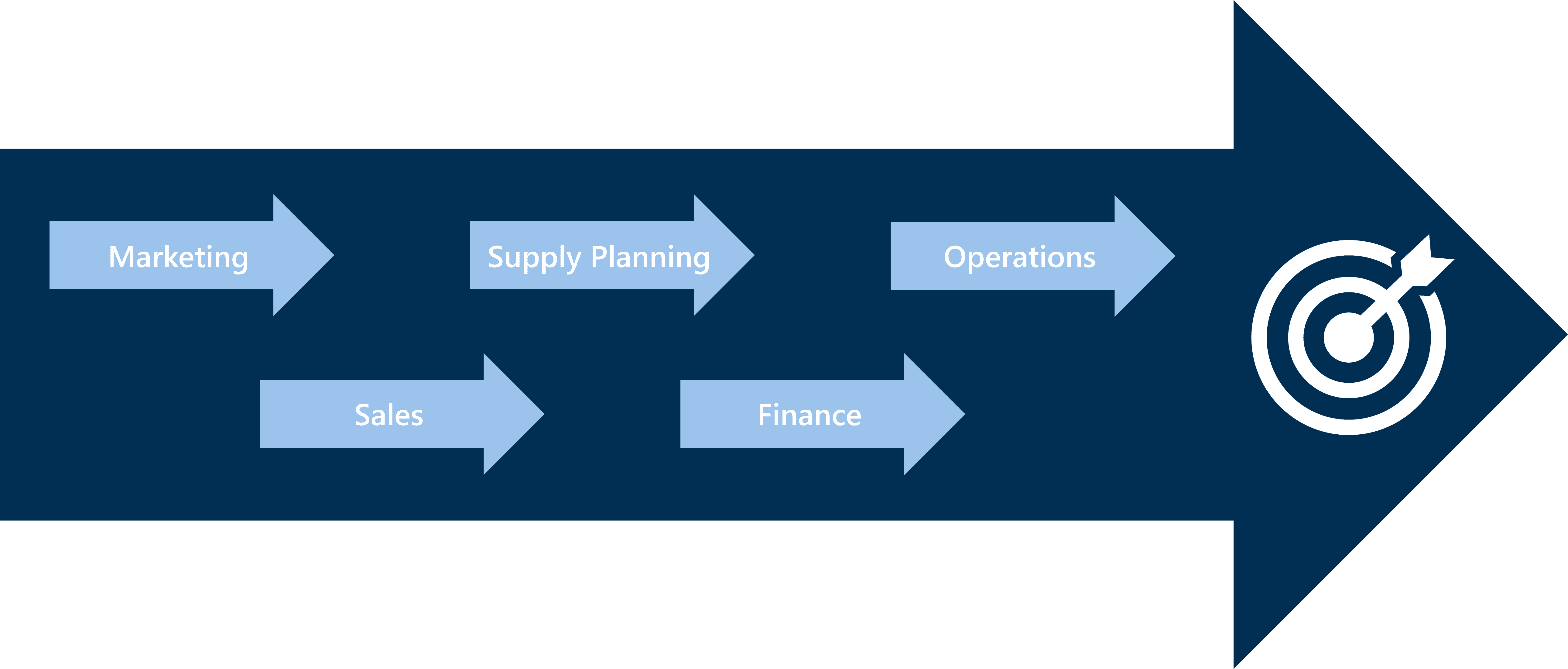

Full Alignment in Sales & Operations Planning Among Different Departments of Manufacturing Enterprise

But how can manufacturers implement S&OP effectively in the digital age?

Digitalizing S&OP: The Plan Optimus Advantage

This is where Plan Optimus steps in. As a leader in digital S&OP solutions, Plan Optimus offers a comprehensive suite of tools designed to streamline and optimize the entire S&OP process.

These digital solutions typically encompass:

1. Demand Forecasting & Planning

Plan Optimus's advanced algorithms provide:

Automatic calculation of base demand forecasts

Multi-level demand forecasting

Promotional and causal demand forecasting

2. Inventory Planning

With Plan Optimus, you can:

Calculate time-phased safety stock

Implement vendor-managed inventory planning

Optimize economic order quantities

3. Production Planning & Scheduling

The platform enables:

Detailed production scheduling

Raw materials planning

Supplier planning and integration

4. Supply Chain Planning

Plan Optimus leverages Digital Twin simulation to:

Automate capacity and fulfillment decisions

Optimize production planning and scheduling

Streamline procurement processes

By implementing a digital S&OP solution like Plan Optimus, companies can achieve:

Higher customer service levels

Optimized inventory

Improved manufacturing efficiency

Enhanced cross-organizational collaboration

Maximized sales revenues

The Multi-Horizon Approach

Successful S&OP implementation requires a multi-horizon digital approach:

Short-term: Focusing on detailed scheduling and execution

Mid-term: Addressing tactical planning and optimization

Long-term: Tackling strategic planning and network design

This comprehensive strategy ensures that all bases are covered, from day-to-day operations to long-term business goals.

Why Choose Plan Optimus?

With a global practice dedicated to S&OP for Industry 4.0, Plan Optimus stands out with:

Deep business process knowledge

Extensive technical expertise

Proven implementation experience

Plan Optimus is equipped to handle even the most complex and unpredictable supply chains across all industrial sectors.

Embracing the Future of Manufacturing

As we navigate the complexities of Industry 4.0, effective S&OP becomes not just an advantage, but a necessity. It's time for manufacturers to embrace this digital revolution and transform their operations.

By leveraging solutions like Plan Optimus, manufacturers can turn the challenge of balancing supply and demand into a strategic advantage.

The future of manufacturing lies in the hands of those who can master the delicate balance of supply and demand - and S&OP is the key to unlocking that potential.

Are you ready to revolutionize your manufacturing processes with S&OP?

Explore how Plan Optimus can transform your S&OP strategy and drive your business towards unparalleled efficiency and profitability.

Contact us at info@planoptimus.com.